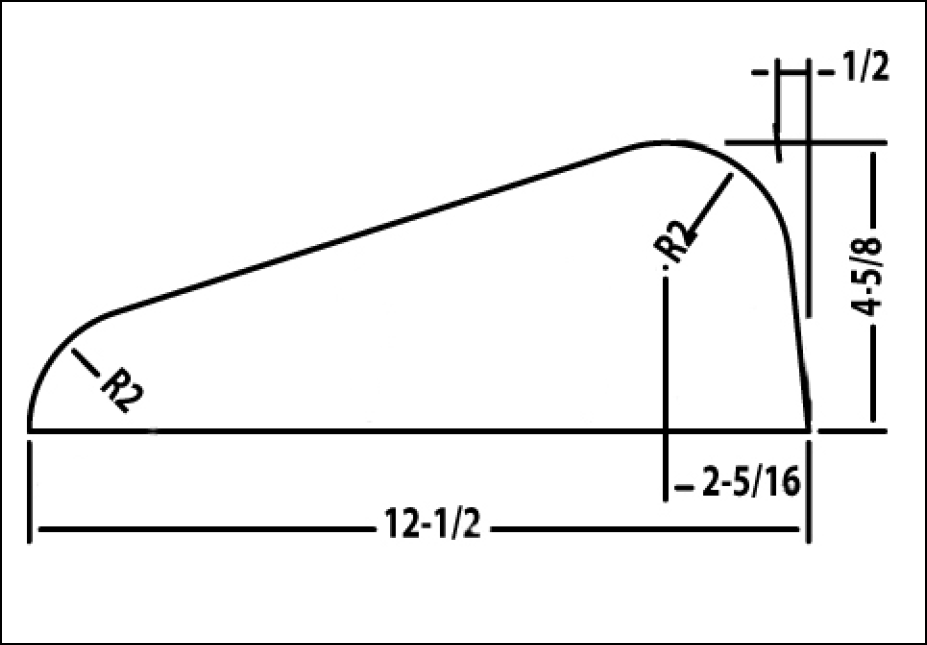

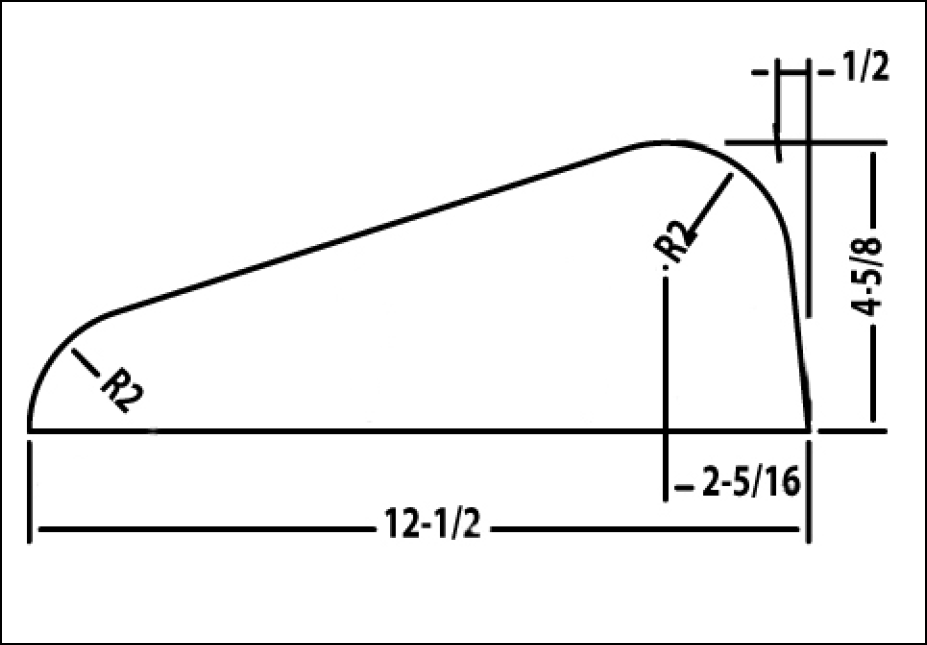

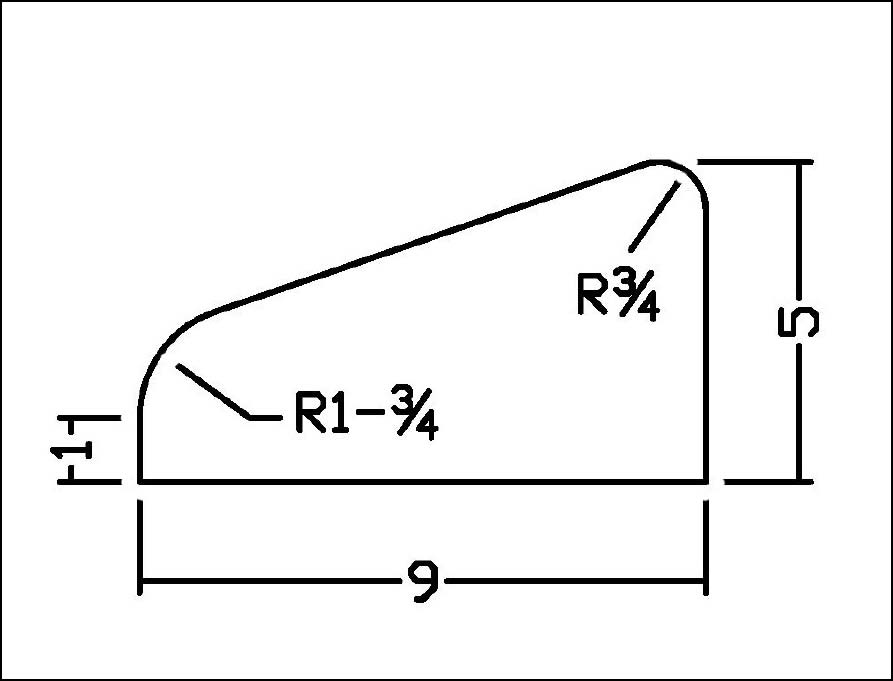

CFD #772

- Area: 33 SQ IN.

- Auger Size: 6 IN.

- 117 Linear Feet per CU YD of concrete

- 58 Linear Feet per Ton of Asphalt

QUICK & EFFICIENT COMMERCIAL CURBER RENTALS BUILT TO GET THE JOB DONE RIGHT

COMMERCIAL CURBER RENTAL NEAR ME:

The MC 550/650 Curb Machines are the bread and butter of all the models we make. They are very versatile curb machines that are designed to handle everything from extruding curb in a parking lot, trench curb, barn curb or curbing along a city street, county road or highway. The only difference between the 2 models is the 550 has a 13 HP Honda recoil start engine and the 650 has a 13 HP Honda electric start engine. For over fifty years the Miller MC Series Curbers have offered unequaled performance and versatility for the placement of freestanding curb. These simple and efficient self-propelled machines operate on the extrusion principle and provide the most economical means available of constructing small to mid-sized continuous curb from either concrete or asphalt. This quick and efficient process drastically reduces the high labor costs associated with hand formed and poured curb and produces high quality, extremely dense curb at a rate of up to 15 fpm (up to 30 fpm for MC900). Miller’s exclusive interchangeable extrusion auger assemblies give each Curber the capacity to extrude more shapes and sizes than any machine in its class, from 3-1/2″ to 18″ high curb. A wide variety of options allow these machines to meet the toughest specification work.

• Every model will extrude concrete or asphalt

• Four interchangeable extrusion assemblies with auger diameters from 5″ to 10″

• Extrude from right or left side of the machine

• Place curb within 1″ of an obstacle

• Extrude steel rod through the curb center (optional hollow auger assembly)

• Two-piece 5″, 6″ and 8″ cast auger allowing four separate wear surfaces for extended life

• Extrude over pins (optional form)

• Easy access and removal of all extrusion components for maintenance and quick clean-up

AVAILABLE CURB FORMS:

CFD #772 | CFD #916 | CFD #647

CFD #772

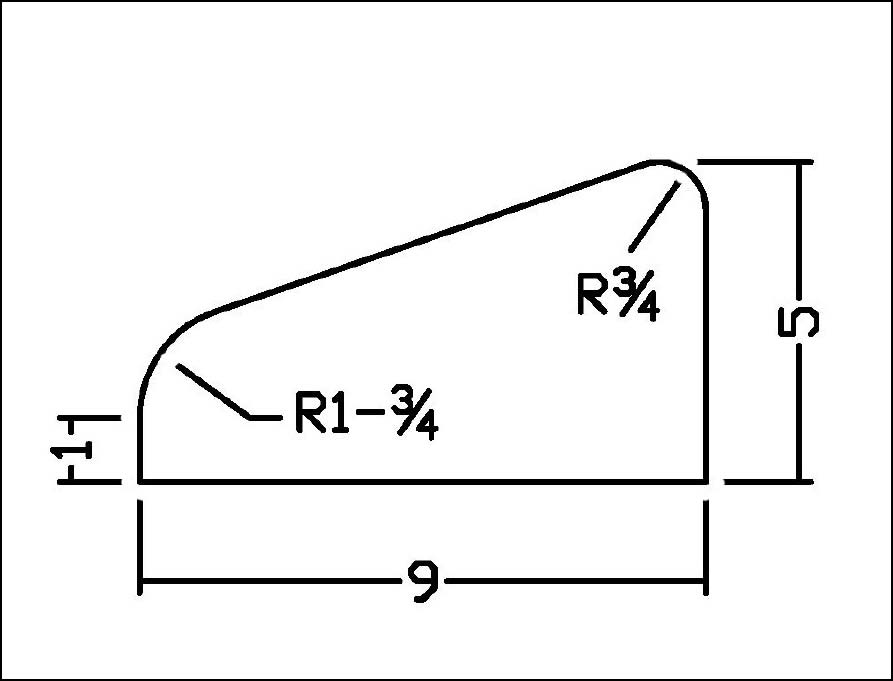

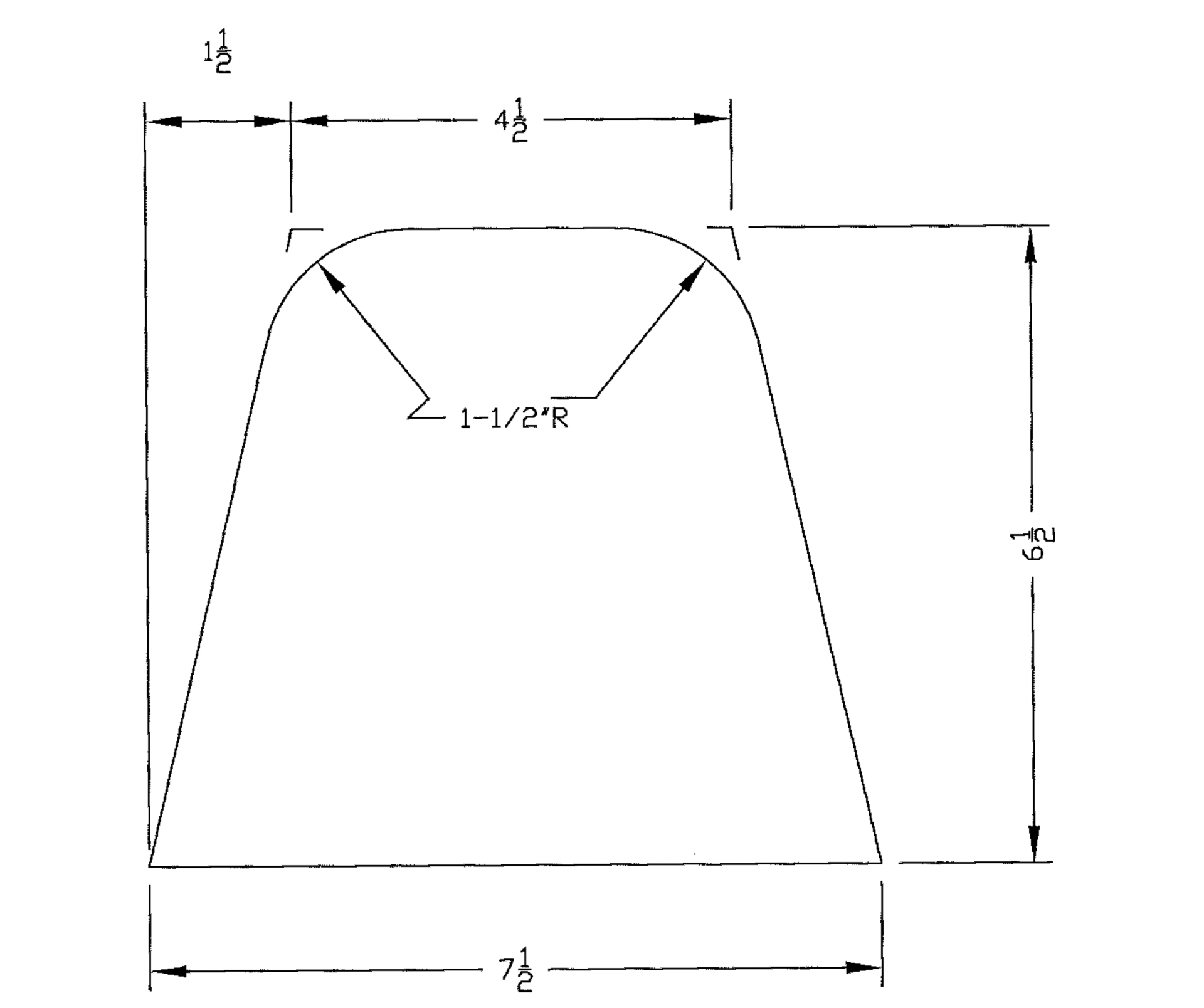

CFD #916

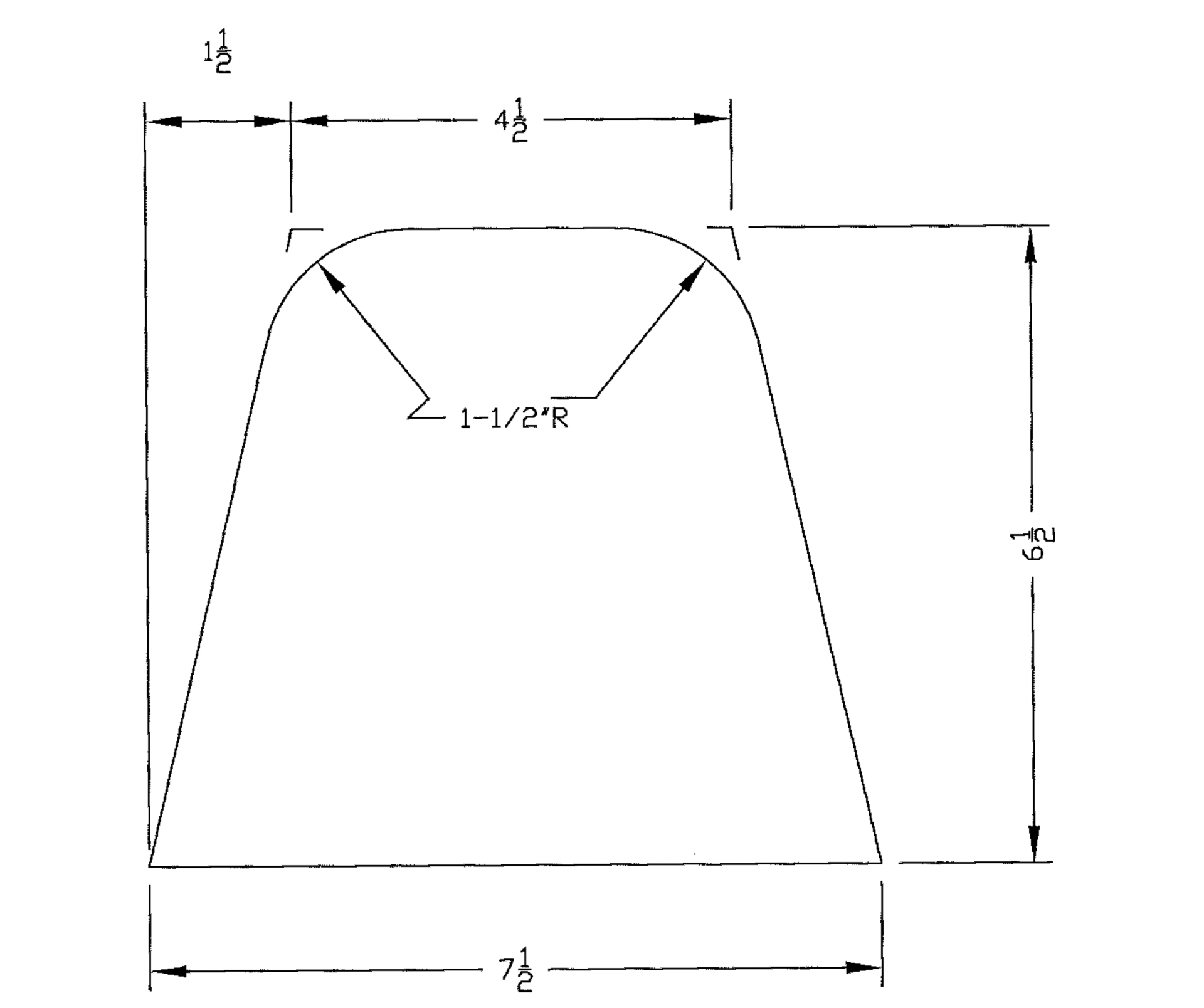

CFD #647- MAINE DOT STANDARD CURB FORM

| MILLER CURBER MC550 | |

|---|---|

| Operating Weight | 668 lb |

| Height | 38” |

| Width | 32.25” |

| Length with From | 77.5” |

| Wheelbase | 52.75” |

| Hopper Capacity | 6.1 cubic feet |

| Standard Tire Configuration | (9) 8” dia. x 2” solid rubber |

| Engine | 13 HP Honda |

| Engine Starting System | Recoil |

| Fuel Capacity | 1.6 gal. |

| Standard Auger Configuration | (2) cast 6” dia. x 9” lg. |

| Optional Auger Configuration | (2) cast 5” dia. x 9” lg. (1) welded 8” dia. x 18” lg. |

| Hollow Auger Shaft | Optional |

| Drive System | Automatic centrifugal clutch to enclosed 8:1 gear reducer; final auger drive chain & sprocket - Extrusion process provides self-propulsion |

| Steering | Tie rod with 40” steering handle |

| Brake | Friction pad on steering handle |

COMMERCIAL CURBER RENTAL NEAR ME:

The MC 550/650 Curb Machines are the bread and butter of all the models we make. They are very versatile curb machines that are designed to handle everything from extruding curb in a parking lot, trench curb, barn curb or curbing along a city street, county road or highway. The only difference between the 2 models is the 550 has a 13 HP Honda recoil start engine and the 650 has a 13 HP Honda electric start engine. For over fifty years the Miller MC Series Curbers have offered unequaled performance and versatility for the placement of freestanding curb. These simple and efficient self-propelled machines operate on the extrusion principle and provide the most economical means available of constructing small to mid-sized continuous curb from either concrete or asphalt. This quick and efficient process drastically reduces the high labor costs associated with hand formed and poured curb and produces high quality, extremely dense curb at a rate of up to 15 fpm (up to 30 fpm for MC900). Miller’s exclusive interchangeable extrusion auger assemblies give each Curber the capacity to extrude more shapes and sizes than any machine in its class, from 3-1/2″ to 18″ high curb. A wide variety of options allow these machines to meet the toughest specification work.

• Every model will extrude concrete or asphalt

• Four interchangeable extrusion assemblies with auger diameters from 5″ to 10″

• Extrude from right or left side of the machine

• Place curb within 1″ of an obstacle

• Extrude steel rod through the curb center (optional hollow auger assembly)

• Two-piece 5″, 6″ and 8″ cast auger allowing four separate wear surfaces for extended life

• Extrude over pins (optional form)

• Easy access and removal of all extrusion components for maintenance and quick clean-up

AVAILABLE CURB FORMS:

CFD #772 | CFD #916 | CFD #647

CFD #772

CFD #916

CFD #647- MAINE DOT STANDARD CURB FORM

| MILLER CURBER MC650 | |

|---|---|

| Operating Weight | 718 lb |

| Height | 38” |

| Width | 32.25” |

| Length with From | 77.5” |

| Wheelbase | 52.75” |

| Hopper Capacity | 6.1 cubic feet |

| Standard Tire Configuration | (9) 8” dia. x 2” solid rubber |

| Engine | 13 HP Honda |

| Engine Starting System | Electric |

| Fuel Capacity | 1.6 gal. |

| Standard Auger Configuration | (2) cast 6” dia. x 9” lg. |

| Optional Auger Configuration | (2) cast 5” dia. x 9” lg. (1) welded 8” dia. x 18” lg. |

| Hollow Auger Shaft | Optional |

| Drive System | Automatic centrifugal clutch to enclosed 8:1 gear reducer; final auger drive chain & sprocket - Extrusion process provides self-propulsion |

| Steering | Tie rod with 40” steering handle |

| Brake | Friction pad on steering handle |

* ALL RESERVATION CANCELLATIONS WILL RESULT IN FORFEITURE OF SECURITY DEPOSIT *

Easy Rent All 20 South Ave, Lewiston, 04240, US 207-784-1541